Here is a cute infographic video from Novamont about bioplastics and bioeconomy in Italy. It shows the Italian case study in the promotion of a new model of economic development focused on the crea...

Get Started for FREE

Sign up with Facebook Sign up with X

I don't have a Facebook or a X account

| Tags |

|---|

Your new post is loading... Your new post is loading...

Amazing cosmos bed made from glass fiber. Built in sound system, and fragrance release. Colorful LED lamps look like stars, can be adjusted according to mood...

New 1pcs violin glass fiber case waterproof Light Durable reinforced Pink #011 in Musical Instruments & Gear, String, Violin | eBay

MaterialsReview's insight:

Interesting.

From

t

RT @AlternativesJ: The bioplastics industry is taking off – and has way more potential than dorky forks made from corn starch. http://t.co/…

Visiting the body shop at Ford’s vast River Rouge site is a disorienting experience. The factory in Dearborn, near Detroit, is eerily quiet compared with the din in most such plants. Via Gino Schiona

With the continuous improvement of modern day machining and the emergence of all sorts of new components as well as the rising demand for machining precision and surface roughness, corresponding sophisticated grinding strategies and abrasives goods, specifically coated abrasives, are establishing towards higher efficiency, longer service life, and super precision. Abrasive belt grinding techniques have stepped into an era of modernized development. Industrial created nations in Europe and America attach fantastic value to the R&D and application of grinding techniques. Even though the abrasive belts’ working life has been improved, the application fields are expanding: abrasives belts can be utilized in wet grinding, dry grinding, high-speed grinding, and higher precision components polishing. The powerful, higher-speed, higher-effective, and precision abrasive belts are not restricted to higher-method coated abrasives products, but far more of products with high added worth. The high quality and regular of abrasive belts is a symbol of a nation’s comprehensive level of coated abrasives and can bring high economic benefits.

Current Scenario of Abrasives Belts

The worldwide developing trend of abrasive belts is speedy. Given that 1960s, the development of electrostatic abrasive grain dispensing and coated abrasives technologies have helped industries developed nations, such as some European nations, America, and Japan, made enormous achievements. With the emergence of special coated abrasives (ceramic abrasives, abrasive compound, grouped abrasives, etc), all varieties of abrasive belts produced of diamond, CBN, zirconia alumina, ceramic abrasives, abrasive compound, and grouped abrasives sprang up. Diamond abrasive belts developed by Japan are successful in processing some supplies of higher hardness, such as monocrystalline silicon wafer. Internationally known brands of abrasive belts contain 3M, Norton, Hermes, VSM, Klingspor, DEER, and so on. Abrasive belt grinders exist in a variety of types. With the development of automation technology, CNC abrasive belt grinder and robot abrasive belt grinding center have been applied.

As a kind of elastic grinding, abrasive belt grinding is a compound method that has the functions of grinding, lapping, and polishing. Considering that the abrasive grains on abrasive belts have a far more potent grinding force than the grinding wheels, the grinding efficiency is really higher in three aspects: removal rate, grinding ratio, and abrasive belt machine tool power availability. Abrasive higher-price grinding has been applied in foreign nations to attain high removal price of metal. So far, the recognized abrasive belt removal rate of steel has exceeded 700cm3/cm•s. Abrasive belt grinding ratio is far beyond the grinding wheels, and abrasive belt machine tool energy availability reached 80% early in the preliminary period. The figure is as higher as 96% presently. For that reason, abrasive belt grinding technique has turn out to be an important approach for industrial developed nations to gain high economic rewards.

Use of Abrasive Belt Grinding

Abrasive belt grinding has formed a full and systematic processing approach soon after 3 decades’ development. It is popular among users thanks to its higher grinding efficiency, wide application fields, strong adaptability, low charges, and simple-to-deal with characteristics. In foreign countries, abrasive belts are capable of processing all kinds of engineering components. Elastic and higher efficiency cold cutting abrasive belts have been extensively used in massive flat thick and thin sheet materials, metal and nonmetal workpieces, complex workpiece forming grinding and polishing, metal tube cylindrical grinding and internal grinding, and so on. Dry grinding disc can replace polishing wheels in polishing approach and be utilized in chip removing and rust removing of massive boxes, ships, and bridges.

Author: Liwei Chu

Related Cnc Engineering Services Press Releases

Via Aluminium Machining China

New #job: Injection Moulding Specialist/ Automotive/ New projects Location: Central Bohemian .. http://t.co/j4nIopGK6m #jobs #hiring

iPhone 4 Aluminium Alloy Battery Door with Paisley Print Supplied by Etradesupply is quality Assured. We Have Broad Sourcing Channel And Strict Process To Guarantee Each iPhone 4 Aluminium Alloy Battery Door with Paisley Print is Totally Good.

Multimaterial 3D printing has often relied on multiple 3D printheads or complex experiments, but RepRapPro’s Adrian Bowyer and Dr Michael Fairhurst have come up with a simple way to make one extruder print many materials. Via Eddy Castro

KOLKATA: Ess Dee Aluminum, one of the country's leading aluminium foil manufacturers, has bagged two awards in International Concept On Quality Convention. The global event, held in Sri Lanka... |

Bekijk de Application Specialist Bioplastics vacature bij Corbion in Gorinchem op Intermediair.nl

DALLAS, November 21, 2014 /PRNewswire/ --

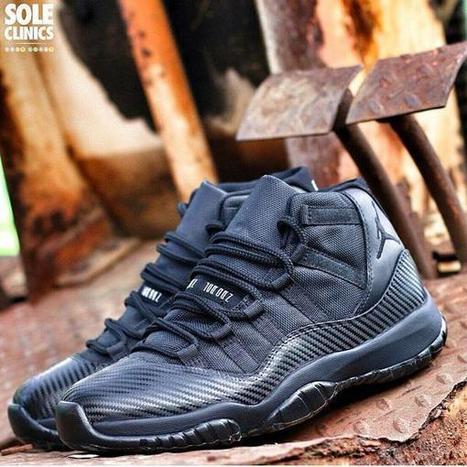

Would you rock these custom Jordan 11 "Carbon Fibers"? pic.twitter.com/Bi74x2JNHY

In Sachen Verpackung waren auf der viscom nicht nur innovative Lösungen der Hersteller zu sehen. In der Packaging Design School ging es auch darum, Gestalter in den kreativen Prozess des Verpackungs-Designs mit einzubinden. Und so traten mit Unterstützung von Fotolia, Wacom, Adobe und dem Magazin DOCMA Studierende Der European School of Design zum Verpackungs-Battle gegeneinander […

Precision Machining for Motorsport at Cam Tech Engineering…investment in a Leadwell machining centre has proved a fantastic investment…read much more about Camtec…

Universal Machining and Engineering is a complete service machine shop equipped with some of the top CNC machines and machinists to perform your job with tight p…

Via Aluminium Machining China

Big area additive manfacturing builds the entire car (the non-moving parts) as a single module. Just add wheels, tires, motor, and battery. Via jean lievens

Persistence Market Research Released New Market Report on “Amino Resins Market: Global Industry Analysis and Forecast to 2020” in the category 'Chemicals and Materials'.New York, NY -- (ReleaseWire) -- 10/06/2014 -- Amino resins are a type of...

TOKYO (Reuters) - Japan's Toray Industries said it will be the sole supplier of carbon fiber for Boeing Co's 777X passenger jet in addition to the 787 Dreamliner and expects

Dow Corning® MB50-010 Masterbatch is an internal lubricant for GE ULTEM® Polyetherimide (PEI). It is provided in the form of pellets and has 50% of an ultra-high molecular weight siloxane dissolved in DuPont HYTRELL® (MI 11).

Luís Bastos's curator insight,

January 17, 2013 2:18 PM

Light-weight non-flammable nanocomposite coatings for cotton fibers were produced by a group of Iranian researchers, using carbon nanotubes and an anti-flammable monomer under UV radiation. |